Beer & Wine

OZONE FOR BEER & WINE

Typically, breweries and wineries wash equipment and pipelines with a solution of hot water and cleaning chemicals products at considerable costs. Also, the residues and harmful chlorides byproducts impact the quality of the product, and the wastewater washed out. Ozone Solutions provides economical and effective solutions to these problems and more.

A primary concern in the wine industry is cross-contamination between batches. Previously, sanitation techniques included using chlorinated cleaners followed by a citric acid rinse to neutralize the chlorine. Barrel sanitation is incredibly challenging because of the porous nature of oak and the possibility of chemical retention; therefore, wineries cannot use chlorinated cleansers in barrels.

Ozone is the most potent disinfectant available and presents several advantages over other alternatives, including higher quality sanitization, decreased contact time, energy savings, and decreased chemical use without the harmful disinfection byproducts. Ozone provides microbiological control for cleaning operations in wineries and breweries, reducing energy consumption and cost.

BENEFITS OF OZONE

A safe, chemical-free process that provides superior taste. Ozone is one of the most potent disinfectants in the wine and beer industries. Yet the ozonation process provides one of the safest methods for your sanitation needs. Ozone offers more environmentally friendly, cost-effective solutions when compared to other traditional chemical options. Ozone Solutions' industry-leading easy-to-integrate technology is ideal for clean-in-place (CIP), odor control, bottle washing, as well as surface and barrel sanitation. It also reduces overall sanitation time.

- Ozone is Generally Recognized as Safe (GRAS) for use in food processing.

- Approved by the FDA, USDA and supported by the National Organic Program

- No harmful chemical residues or byproducts that require a final rinse

- Instant pathogen destruction (Microorganisms Ozone Eliminates)

- No need for chemical storage, shipping, or delays

- Removes airborne microbes and improves odors

- 3000x more germicidal than chlorine

- Sustainable, environmentally friendly

- Lower cost of wastewater disposal

- Water and energy efficiency

- Extends product shelf life

Applications for the Wine Industry

- Tank and Press Sanitation

- Bottling Washing

- CIP (Clean in Place)

- Surface Sanitation

- Barrel Sanitation and Storage

- Irrigation

Applications for the Beer Industry

- Fermentation and Tank Sanitation

- Bottle Washing

- CIP (Clean in Place)

- Surface sanitation

- Keg and Barrel Sanitation

- Odor Control

LEARN MORE SPECIFICS ABOUT:

Typically, 2.5 ppm ozone concentration for 2 mins on healthy barrels after a hot water flush is sufficient (in case of severe contamination, 2.5 ppm ozone concentration for 5 mins). Ozone enhances the barrels by preventing organic buildup. Ozone washing of wine barrels saves wineries considerable money on the high costs of replacing contaminated wine barrels. As a result, Ozone Solution’s installations yield a very high return on investment.

The range of surfaces and equipment is routinely sanitized with ozonized water to control unwanted microbes and cross-contamination. Harvest bins, crushing and de-stemming machines, conveyors, and even floors are routinely and effectively sanitized using ozone. Bottles and bottling equipment are sanitized with ozone as well.

Breweries use ozone for initial sanitation and additional follow-up rinses throughout the process. Stainless steel tanks may stand empty for a week or more after initial sanitization. Many wineries chose to rinse all stainless-steel vessels with ozonized water directly before filling.

Transferring the wine between tanks and barrels results in the highest risk of contamination in the winemaking process. Many wineries have adopted stringent measures to their CIP processes in order to mitigate this risk.

CIP involves the cleaning and sanitizing pump systems, pipes, tanks, hoses, filters, bottling lines, etc. Without ozone, using detergents, pressurized water, and chemicals like bleach solutions, these cleaning steps may require multiple rinses, often with hot water or steam, to remove residues into the wastewater. The use of chemicals also generates concern and risks for the safety of workers and the pollution of groundwater.

Ozone treatments are an integral part of CIP sanitization in the food processing industry and are a natural choice for beer and wine process machines. Using our Mobilezone generators for CIP saves time and costs.

Ozone Solution’s engineers will happily provide you with a custom design for your needs and technical assistance in selecting the correct system and applications for your operations to fit your budget.

| Common Systems Used In The Beer & Wine Industries | ||

|---|---|---|

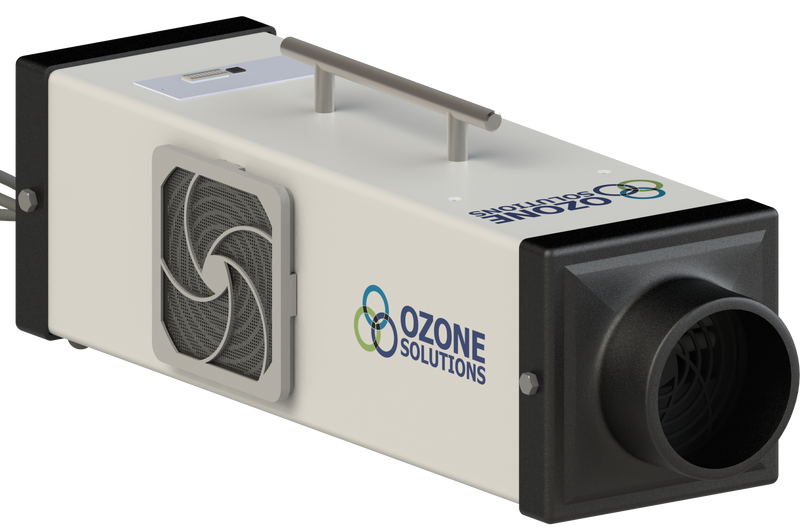

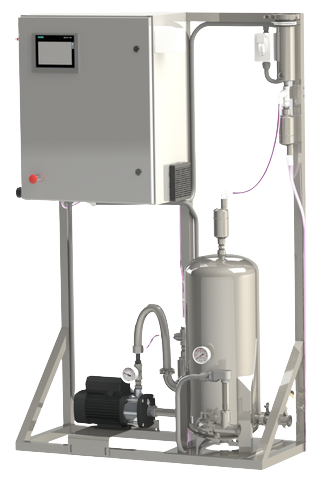

| DR Series Ozone Units | MobileZone | WaterZone |

|  |  |

| Works well in high humidity environment | Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator |

| High flow fans | Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level |

| Low maintenance | Compact, mobile design | Customizable system can be configured for your specific application |

| Portable and lightweight | Ozone Destruct included for added safety | All plumbing and fittings are stainless steel |

| DR Series | MobileZone | WaterZone Series |