Ready To Eat (RTE)

For Ready-To-Eat (RTE) food processing, ozone is useful in both food production and product packaging. The USDA and FDA approve ozone as a preventive step for airborne and foodborne pathogens. Treating food additives or completed products with gas ozone or aqueous ozone has been proven to reduce harmful contaminants. Ozone can also be used during prepackaging to minimize the possibility of introducing harmful microbes. Ozone is used heavily in the bottled water industry to treat water and bottles before being filled. In recent ozone testing on sauce packages, the application reduced listeria and salmonella by 6-logs.

Ozone Solutions can Design a System to Treat:

- Unfinished Product

- Production Equipment

- Hard surface Sanitation

- Packing Materials

- Finished Product

Ozone Benefits for RTE Food Production:

- Approved by the FDA, USDA

- Sustainable and generated on-site

- Supported by the National Organic Program

- Improves operating, maintenance, and chemical costs

- Removes the need to handle or store harsh chemicals

- No harmful chemical byproducts that require a final rinse

- Removes airborne contaminants and improves odors

- Superior disinfection due to high oxidation state

- Improves water and energy efficiencies

- 3000x more germicidal than chlorine

- Lowers cost of wastewater disposal

- Removes pathogens instantly

- Increases shelf life

- Eliminates Ethylene

| Scientific Publications |

|---|

| Recent Ozone Applications in Food Processing and Sanitation |

| Meat Industry Services-Ozonated Water |

| Ozone Sanitation-A Sustainable and Efficacious Approach to Food Safety |

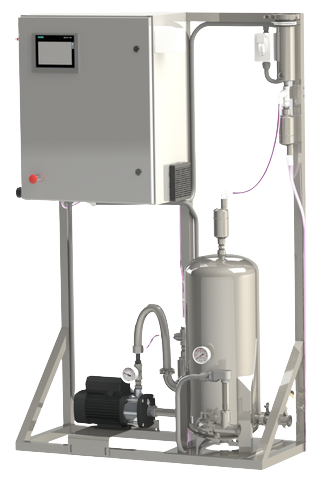

| Common Systems Used For RTE Food Production | ||

|---|---|---|

| MobileZone | WaterZone Series | DualZone Series |

|  |  |

| Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator | The Dualzone can create Aqueous (ozonated water) or Gaseous ozone for a highly versatile machine |

| Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | Standard DualZones produce 60 grams of ozone/hour |

| Compact, mobile design | Customizable system can be configured for your specific application | Water flow from 1-300 gpm |

| Ozone Destruct included for added safety | All plumbing and fittings are stainless steel | Ready to use upon delivery |

| MobileZone | WaterZone Series | DualZone Series |