Dairy Operations and Ozone

Ozone treatment is an eco-friendly and cost-effective industrial technology. The method has successfully been used to remove milk residue and biofilm-forming bacteria from surfaces in milk processing. Sterilizing tools help ensure milk quality, safe dairy products, up to standards, and an overall cleaner environment. In many stages of the process, ozone applications can clean the environment and disinfect products with high treatment efficiency.

The livestock drinking water is one of the main factors determining the quality of milk output. Water sources include well water, river water, tap water, etc. These water sources may be purified or not, but most contain bacteria, viruses, molds, and heavy metals. Dairies use ozone treatments to remove these pathogens and metals.

The livestock drinking water is one of the main factors determining the quality of milk output. Water sources include well water, river water, tap water, etc. These water sources may be purified or not, but most contain bacteria, viruses, molds, and heavy metals. Dairies use ozone treatments to remove these pathogens and metals.

Reduce livestock exposure to contaminants. Ozone prevents infections and illness increasing milk production and decreasing veterinarian costs. Compared with conventional methods, such as copper sulfate, an ozone solution increases efficiencies and reduces costs.

Dairy Tools and Equipment

Ozone can also be used for cleaning tools. Ozone is not only used to care for livestock. Ozone can also disinfect the living environment, milk containers, milking tools, and the storage environment. Also, Ozone increases preservation time as well as product shelf life.

Food Safety in Dairy Operations

Implementing good hygienic practices on dairy farms produces high-quality, safe raw milk. Ozone is a powerful oxidizing agent active against various microorganisms, including viruses, bacteria, yeasts, molds, and protozoa.

The pipelines which carry the milk from individual milking stations to the bulk tank must be cleaned after every milking. Using chemicals and hot water for the cleaning and disinfection processes consumes a large amount of energy, water, and chemicals that then washes out into the groundwater.

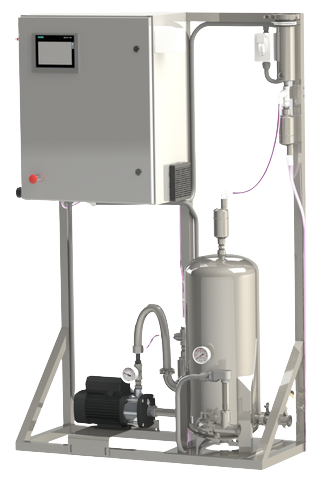

The use of ozone can considerably reduce chemical and water costs on dairy farms. Ozone Solution's Dualzone System delivers ozonated water, which contains ozone at a preferable level of 0.04–1.2 ppm and is used to clean and disinfect animals, milking equipment, and various surfaces within the dairy. Many hygienic problems can be prevented by washing the animal’s hind legs, udder, and teats with ozonated water before milking.

Another use of ozone at dairy farms is a low concentration air treatment in the barn to destroy airborne pathogens and eliminate that pungent manure smell. Ozone has even been successfully used to treat bovine mastitis, one of the most common and costly diseases to affect dairy production. When 6–30 mg of ozone was infused into each inflamed udder with acute clinical mastitis, 60% of the animals completely recovered without antibiotics. In these cases, the efficacy of ozone therapy was identical to antibiotic treatment. Ozone therapy is a safe, effective, and inexpensive method of curing mastitis without leaving antibiotic residues in raw milk.

| Blogs |

|---|

| Ozone In Dairy Productions |

| Ozone In Wastewater |

| Hard Surface Sanitation (CIP) |

| Whitepapers |

|---|

| Use of Ozone in the Dairy Industry |

| Removal of Dairy Soil from Heated Stainless Steel Surfaces |

| Common Systems Used For Dairy Operations | ||

|---|---|---|

| MobileZone | WaterZone Series | DualZone Series |

|  |  |

| Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator | The Dualzone can create Aqueous (ozonated water) or Gaseous ozone for a highly versatile machine |

| Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | Standard DualZones produce 60 grams of ozone/hour |

| Compact, mobile design | Customizable system can be configured for your specific application | Water flow from 1-300 gpm |

| Ozone Destruct included for added safety | All plumbing and fittings are stainless steel | Ready to use upon delivery |

| MobileZone | WaterZone Series | DualZone Series |