Ozone In Seafood Processing

Utilizing ozone technologies will eliminate bacteria, viruses, mold, and other contaminants more quickly and effectively than chemical treatments. Ozone applications can disinfect boats, warehouses, fresh meat, and trucks. We can work together to create a custom system for a safer and healthier operation for any facility. Let us know how we can help.

Ozone is a safe disinfectant and oxidizer that controls and eliminates microorganisms in food and equipment. Ozone is generated on-site, meaning it’s sustainable. There’s no need to purchase, ship, store, handle or mix chemicals. Ozone can be used for surface disinfection and storing raw commodities, while the physicochemical characteristics of the food remain. Ozone can be applied in storage spaces and surfaces, eliminating all microorganisms it encounters, including bacteria, viruses, fungi, and algae. With regulatory approval, ozone has become the best eco-friendly disinfection. It is also the best choice for cost-effective food disinfection. Ozone improves the microbiological safety of food products and extends their shelf life without changing nutritional, chemical, and physical properties. This process gives the company a greater assurance of food safety while substantially reducing spoilage and water usage.

Ozone Benefits for Processing & Storage:

- Approved by the FDA, USDA

- Supported by the National Organic Program

- More cost-effective long-term compared to ongoing chemical costs

Eliminates mold from the area dedicated to cold storage

Eliminates mold from the area dedicated to cold storage- Reducing foul odors by eliminating airborne pathogens

- Increases the number of live animals and their weight

- Reduces the risk of cross-contamination of pathogens

- Leaves no chemical residue requiring a final rinse

- Eliminates the shipping, storage, of chemicals

- Reduces BOD/COD in wastewater treatment

- Improves water and energy efficiency

- Lowers costs in the waste disposal

- Reduces overall cleaning time

Ozonated Ice for Storage and Shipping

Ozone gas is dissolved into water, then fed into an ice-making machine to capture ozone inside the ice. This ozonated ice is used to store seafood to prolong shelf-life and maintain a fresher, better-looking product for the consumer. Research in France in the commercial fish industry showed a 33% extension in shelf-life of fresh fish stored on ozonated ice compared with regular ice.

| Common Systems Used In The Seafood Industry | ||

|---|---|---|

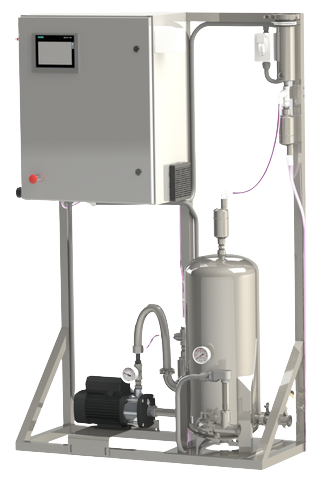

| MobileZone | WaterZone Series | DualZone Series |

|  |  |

| Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator | The Dualzone can create Aqueous (ozonated water) or Gaseous ozone for a highly versatile machine |

| Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | Standard DualZones produce 60 grams of ozone/hour |

| Compact, mobile design | Customizable system can be configured for your specific application | Water flow from 1-300 gpm |

| Ozone Destruct included for added safety | All plumbing and fittings are stainless steel | Ready to use upon delivery |

| MobileZone | WaterZone Series | DualZone Series |