Bottled Water

Ozone treatment has played a role in water bottling plants since the 1970s. At that time, the industry was in its infancy and faced ongoing challenges with bacteria contamination during production and sterile handling and storage afterward. The presence of microorganisms significantly impacted taste and smell, and the lack of disinfection also raised severe health concerns.

In 1982, the FDA classified ozone as safe in water disinfection applications. Ozonation of water provides an efficient, safe method of disinfecting against pathogenic waterborne microorganisms and other bacteria, viruses, mold, and algae. As a fast-acting and effective treatment technology, ozone treatment is widely used in the bottled water industry

Other Benefits of Ozone in Bottled Water

According to International Bottle Water Association (IBWA), ozone is safe and effective and leaves no chemical residue or taste in the final bottled water. The disinfection of both water and container also serves to extend shelf life. There are other benefits to using ozone for bottled water:

- Only byproduct is oxygen

- Destroys pathogens instantly

- Sustainable and generated on-site

- Works faster than any other oxidant

- No need to handle or store harsh chemicals

- Superior disinfection due to high oxidation state

- Improves operating, maintenance, and chemical costs

The Ozonation Process

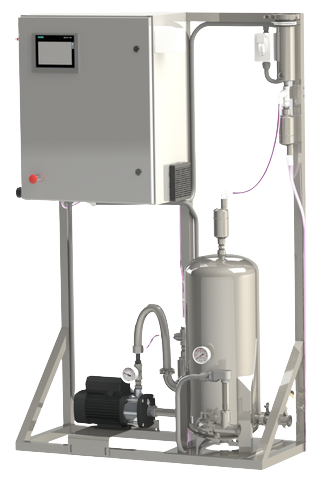

Ozone is broadly used in the bottled water market for its safety, simplicity, and effectiveness. The ozonation process for bottled water involves a low concentration of ozone dissolved into the water just before bottling to disinfect the water, bottle, and cap. The method and system design are relatively straightforward. An integrated ozone injection system consists of an ozone generator, venturi injector, and recirculation pump. Ozone sensors can monitor the ozone concentration at the injection point, the storage tank outlet, after the destruct unit, and at the end of use.

Risks of Ozone in Bottled Water

Although ozone is created from and reverts to oxygen, it must be used according to FDA, EPA, OSHA, and manufacturer guidelines to be safe. The IBWA suggests a residual ozone level of 0.2 to 0.4 ppm. This provides safe disinfection to both the water and the bottle. Other risks to be aware of include:

- Over-ozonation of the water may lead to taste problems due to a high level of ozone

- Non-ozone compatible materials in contact with ozone can lead to contamination

- The sterilization protection disappears after 20-30 minutes

- When oxidated incorrectly, it can form bromate.

Many, if not all, of the risks associated with ozone are directly related to the quality of the ozonation equipment and adherence to guidelines.

Why Choose Ozone Solutions for Bottled Water?

Ozone Solutions has been a leader in disinfection for 25 years. We provide options from hand-held portable ozone monitors to small commercial generators to large-scale industrial ozone systems for both air and water disinfection. We also serve as consultants to help define industry guidelines.

Ozone Solutions has developed an extensive line of water disinfection options for the bottled water industry, providing standardized solutions as well as custom-tailored products to meet customers’ specific applications. We offer engineering, integration consultation, and on-site support. Every custom Ozone Solutions system features specifically designed to simplify installation and maintenance while seamlessly integrating into your current process.

In addition, we are the parent company of Hess Machine. Hess has been the bottled water industry's leading supplier of ozone disinfection systems for over 60 years. Hess machines’ standardized configurations enable smaller operations to get the benefits of ozone, using the highest quality equipment at a cost-effective entry point.

| Scientific Publications |

|---|

| Drinking Water Treatment - Ozone |

| Disinfection |

| Ozone for Bottled Water |

Ensure you get the right solution to your specific needs

| Common Systems Used In The Bottled Water Industry | ||

|---|---|---|

| HESS Series | WaterZone Series | |

|  | |

| Designed specifically for the Bottled Water Industry | Produces ozone from integrated Oxygen Concentrator | |

| Only compressed air and electricity are needed for operation. | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | |

| Highly reliable and robust | Customizable system can be configured for your specific application | |

| Hess machines are great for pre-treating and for disinfection | All plumbing and fittings are stainless steel | |

| Hess Series Generators | WaterZone Series | |