Static Mixer in Action

What Happens Inside a Static Mixer?

If you think using just a venturi injection system is good enough, think again. Venturi injectors do attain fairly good mass transfer, but using a static mixer can greatly improve your mass transfer efficiency. See the image below.

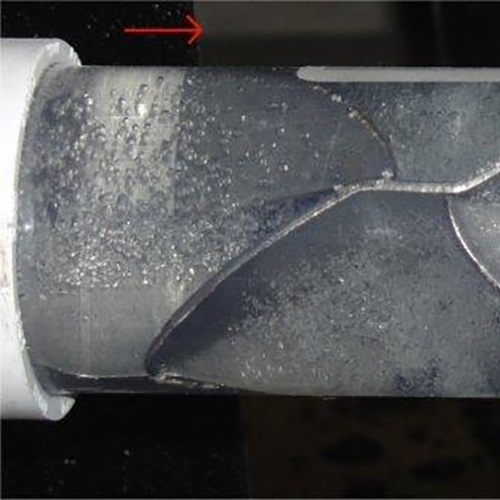

Close-up of Static Mixer Bubble Shearing Action!

(picture taken at 1 millisecond exposure time)

Notice how the bubbles are sheared into much smaller bubbles as they move from left to right resulting in significantly greater ozone mass transfer than using a venturi alone. Pipe size is 1-1/2" diameter.

What is a Static Mixer?

Static mixers are a series of geometric mixing elements fixed within a pipe, which use the energy of the flow stream to create mixing between two or more fluids or gases.

Static Mixer Facts:

- Target Water Velocity is 5-10 ft/sec: Low water velocity through the

mixer results in poor bubble shearing; high water velocity results in higher pressure drop and does not significantly improve mass transfer efficiency

mixer results in poor bubble shearing; high water velocity results in higher pressure drop and does not significantly improve mass transfer efficiency - Static mixers do not require any maintenance - no moving parts!

- Must be installed within 12 inch prior to a contact tank

Determining Velocity in a Static Mixer

V = (Q x 0.402)/D2

[V = Q times 0.402 divided by the Diameter squared]

Q is flow rate in gallons per minute (gpm)

D is diameter in inches

V is the velocity in feet per minute (fpm)

For the MX-Series, optimum water velocity through the static mixer must be between 5-10 feet/second.