Venturi Injectors vs Bubble Diffusers

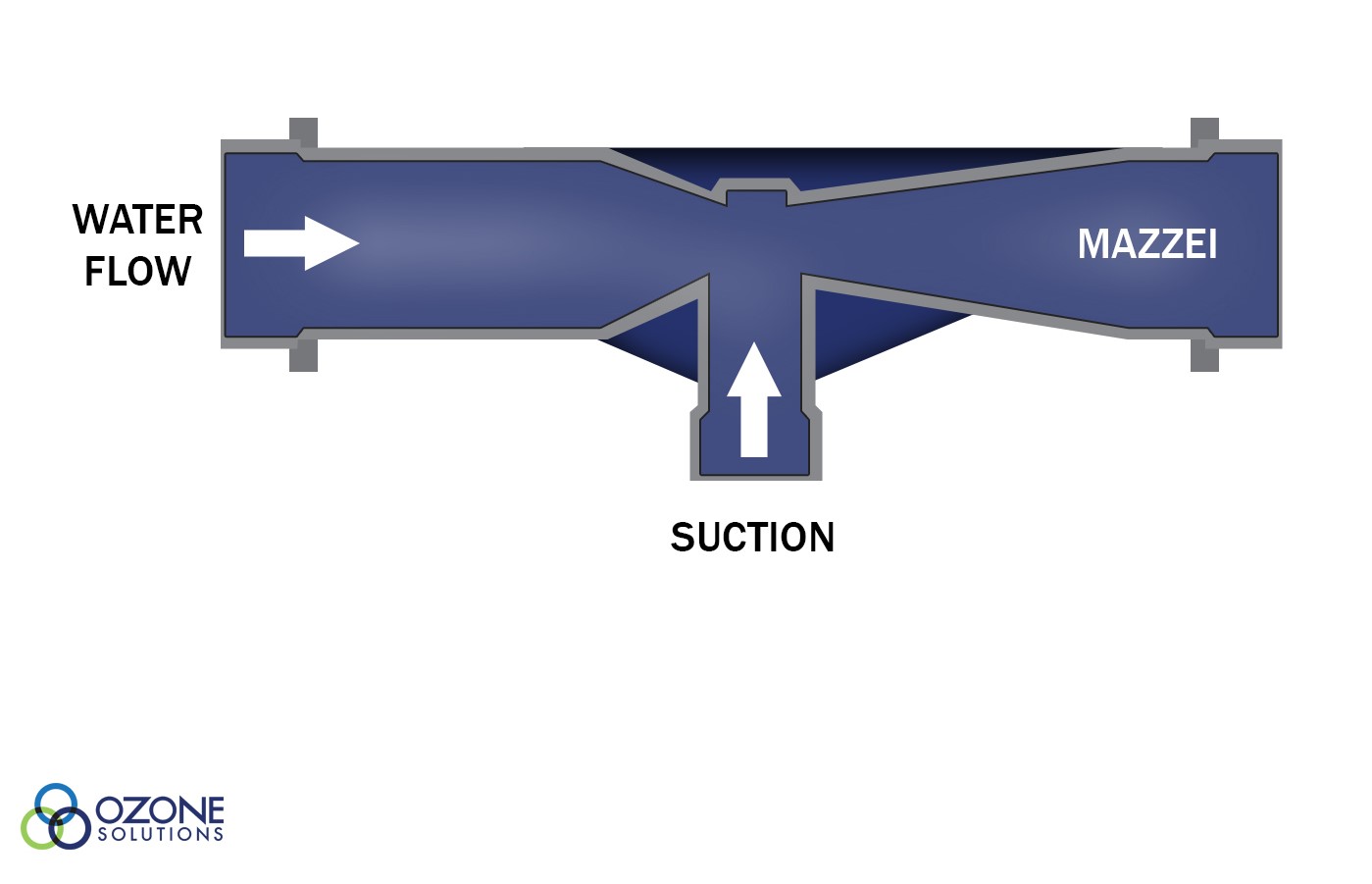

Venturi injectors work by forcing water through a conical body which initiates a pressure differential between the inlet and outlet ports. This creates a vacuum inside the injector body, which initiates ozone suction through the suction port.

Example Ozone Injector / Venturi

Water flow from left to right; ozone is introduced into the middle.

Water flow from left to right; ozone is introduced into the middle.

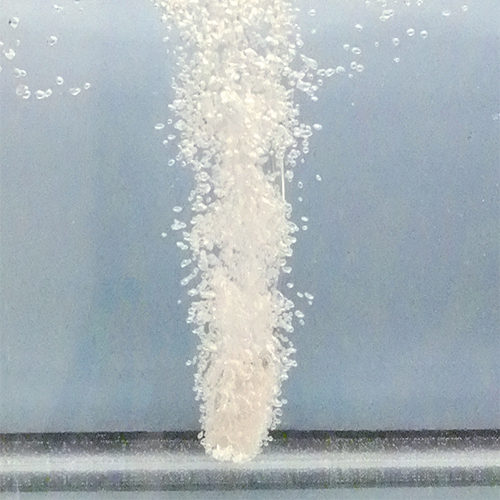

Air is sucked into a venturi injector - Notice the thousands of small bubbles present after the suction port.

The injector produces thousands of bubbles, greatly increasing the surface area of oxygen or ozone in contact with the water. (Two small bubbles have a greater surface area than one large bubble of the same volume.) This results in a very high mass transfer rate.

Characteristics

- Very high ozone mass transfer rate (up to 98% if pressurized, 50-70% w/out pressure)

- Requires water pump to initiate suction

- Efficiency rarely decreases over time

- No moving parts

Bubble Diffusers

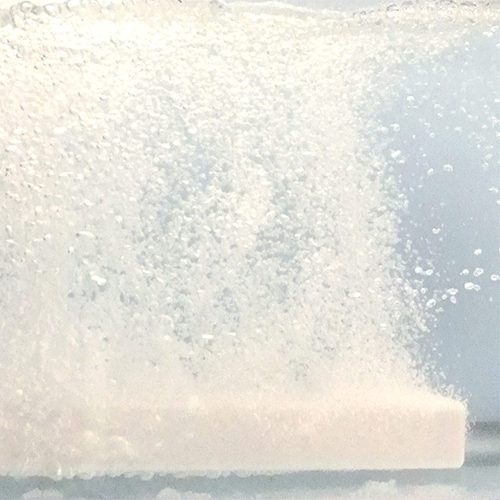

Bubble Diffusers work by emitting ozone through hundreds of bubbles beneath the water's surface.

Characteristics

- Low ozone mass transfer rate (typically around 10-15%)

- Efficiency increases with increased water depth

- Requires air-pump to transfer oxygen below surface

- Diffuser holes become fouled decreasing transfer efficiency

Bubble Diffuser In Action