Ozone Use in Cooling Tower Water Treatment

The use of ozone in cooling tower treatment has received a vast amount of attention in recent years for the benefits it offers the industry.

Ozone Benefits for Cooling Towers

- Safe and easy to use

- Ozone decomposes organic waste

- Very effective in removing biofilms

- Environmentally friendly treatment

- Ozone is effective in a wide pH range

- Ozone requires no additional disinfectants

- Ozone is 3,000x more germicidal than chlorine

- Reduced permit costs for treated water discharge

- Very effective against due to good biofilm removal capacities

- Destroys all types of microorganisms instantly, including Legionella

- Low corrosion rates in the system, including copper heat exchangers, because there are no chlorinated compounds

- Disinfectant with a high-efficiency level (an ozone concentration of 0.1 to 0.2t ppm is, in most cases, very effective in keeping the cooling tower and the cooling circuit clean)

- Ozone does not leave any chemical residues. Ozone’s only byproduct is oxygen.

Operational Savings

Ozone treatment systems in cooling towers also allow for significant savings by:

Ozone treatment systems in cooling towers also allow for significant savings by:

- Reduced maintenance

- Reduced consumables

- Reduced water consumption

- Reduced anti-scaling and anti-corrosion agents

- Reduced energy consumption due to increased efficiency

- Remove the need for chemical shipping, storage, and handling

Read more about Ozone and Water Treatment

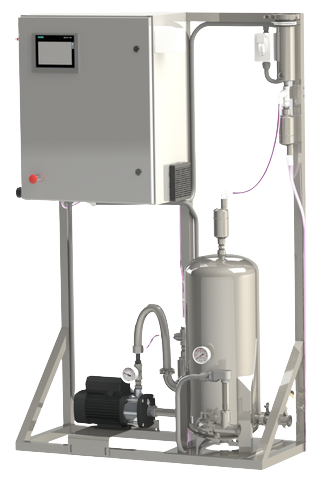

| Common Systems Used For Cooling Towers | ||

|---|---|---|

| Turnkey Systems | WaterZone Series | |

|  | |

| Turnkey ozone generator with integrated oxygen concentrator | Produces ozone from integrated Oxygen Concentrator | |

| Can produce high concentrations of ozone at lower flow rates | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | |

| Wall mountable | Customizable system can be configured for your specific application | |

| Adjustable output & flowmeter comes standard | All plumbing and fittings are stainless steel | |

| Turnkey Systems | WaterZone Series | |