Ozone Applications for the Healthcare Industry

Ozone therapy has been utilized and heavily studied for more than a century. Its effects are proven, consistent, safe, with minimal and preventable side effects. Ozone is an eco-friendly sanitizer against bacteria, viruses, mold, yeast, and protozoa. Ozone Solutions' industry-leading technology and advanced testing lab are equipped to take the healthcare industry to the next level. Ozone treatments can be utilized in various ways to sterilize rooms, equipment, tools, air, and wastewater. Utilizing ozone can eliminate having to use other biohazard disposal services and processes.

Ozone Applications:

- Surface disinfection

- Air purification

- Wastewater treatment

- Equipment disinfection

Ozone Benefits:

Takes up less space and less equipment than many other chemical treatment/storage systems

Takes up less space and less equipment than many other chemical treatment/storage systems- Quicker sanitation: avg. cleaning time reduced by 30% to 75%

- Generated onsite, less liability with shipping and handling

- Ozone can be turned off instantaneously by UV at 254 nm

- Saves money by eliminating the ongoing chemical costs

- No chemicals are added to the facility's waste stream

- Only byproducts is oxygen and no residuals

- No chemical transportation/storage

- No required flushing of the system

- Short contact time

- No heat required

Wastewater Pharmaceutical Residue

Ozone is an ideal method of removing pharmaceutical residue. The level of pharmaceutical compounds in drinking water can be in parts per billion (ppb). Studies show that pharmaceuticals in water may be responsible for some genetic malfunctions in animals and humans. Ozone Solutions' industry-leading technology has proven to be a safe and cost-effective sanitizing approach for the pharmaceutical industry.

Please Note: Ozone Solutions Inc. provides industrial-grade equipment for medical sanitation, not intended for any medical procedures or human consumption.

The USDA accepted ozone as suitable for use in the production of meat and poultry products in 2000, and the FDA approved ozone as an antimicrobial agent for food in 2001 eCFR. At the time, however, ozone was considered only a sanitizing agent. Food processing facilities were still forced to rely upon conventional methods such as hot water rinses and degreasers for cleaning. As a result, ozone enjoyed limited commercial success.

| Common Systems Used In The Medical Field | ||

|---|---|---|

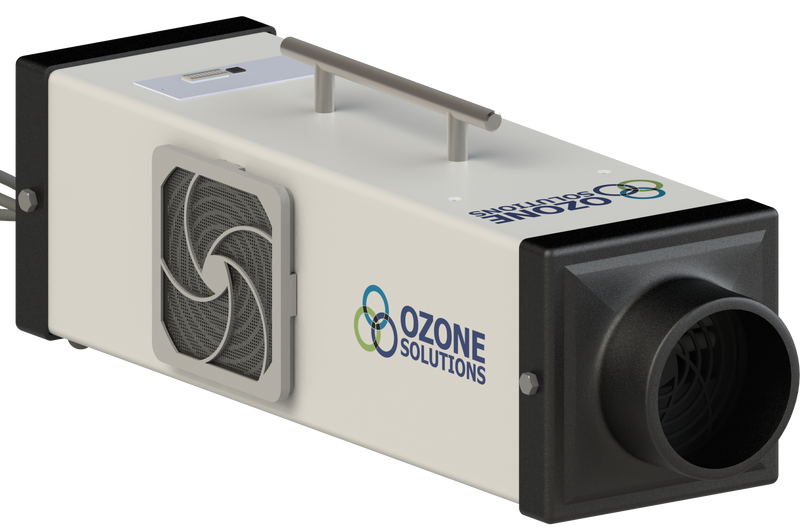

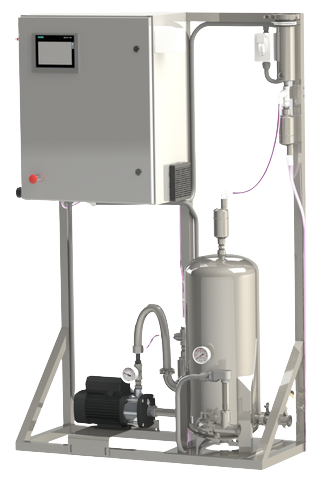

| DR Series Ozone Units | MobileZone | WaterZone |

|  |  |

| Works well in high humidity environment | Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator |

| High flow fans | Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level |

| Low maintenance | Compact, mobile design | Customizable system can be configured for your specific application |

| Portable and lightweight | Ozone Destruct included for added safety | All plumbing and fittings are stainless steel |

| DR Series | MobileZone | WaterZone Series |