Surface Sanitation

In food processing it is important to provide pathogen free food products. Keeping food products pathogen free and reducing the potential for cross-contamination of potentially deadly pathogens is very crucial, and that is why surface sanitation is so important. This page will provide some detail on the potential use of ozone for surface sanitation.

Many processing plants already use ozone-in-water or aqueous ozone for antimicrobial intervention steps directly on the surface of food products. Due to the FDA and USDA giving ozone GRAS (Generally Recognized as Safe) approval for use directly on the surface of all food products, the use of ozone has spread dramatically in the last 10 years. Ozone use for surface sanitation is just one more cost saving method that can be implemented by plants already using ozone, or for plants that would like lower cost and have a more effective method for surface sanitation.

One of the major concerns for cross-contamination on food processing equipment is biofilm build-up. Biofilms are layers of microorganisms bonded tightly to a surface. Microbes can attach themselves to a surface and continue to grow layer upon layer of new microbes. The new layer of microbes can provide nutrients and protection against sanitizers to the existing layers of microbes. These layers of microbes can continue to grow and become more resistant to sanitizers over time making sanitation more difficult if proper sanitation is not achieved on a regular basis. These resistant biofilms are most common in cracks, crevices and corners of food processing equipment that are only sanitized periodically.

CDC estimates that each year roughly 1 in 6 Americans (or 48 million people) gets sick, 128,000 are hospitalized and 3,000 die of foodborne diseases.

Go to CDC Website

Chemical Drawbacks

A common sanitizer in the food processing industry is chlorine. Chlorine is mixed with water providing chlorinated water to be used as a sanitizer. Some microorganisms such as E.coli and Giardia can build resistance to chlorine over time. This may make chlorine less effective than desired over time. Chlorine residual in waste water can also be regulated and make water recirculation or discharge more difficult due to chlorine residuals in the water.

One more drawback to chlorine and other chemicals is the harsh effect they may have on equipment made of metals and wood. Common issues are steel components that chlorinated water is constantly exposed to, shortening the life of potentially expensive equipment. Wooden wine barrels are also damaged by harsh chemicals. Winemakers take special care to choose high quality wooden barrels to age wine in, this wood can be damaged or altered to the point it no longer serves the original purpose.

Ozone in Water Application

Ozone can be dissolved into water just as chlorine and other chemicals can be. In many plants ozone injection systems that provided aqueous ozone may already be in place for use on food products for anti-microbial intervention. Aqueous ozone can be sprayed any way within the plant safely. Equipment, walls, floors, drains, tanks, tubs, racks, knives and tables can all be

sprayed with aqueous ozone. Enclosed piping can also be sanitized with ozone using a Clean in Place (CIP) system.

sprayed with aqueous ozone. Enclosed piping can also be sanitized with ozone using a Clean in Place (CIP) system.

During sanitation with ozone, a two-step process is generally required. Surfaces are cleaned and bio-films are removed with a hot water or cleaning step. Then, aqueous ozone is used to sanitize the surface destroying all bacteria, viruses, fungi and spores. No other sanitation step after the use of ozone is necessary. In fact, no rinse step is necessary after ozone as the ozone will leave no residual on the surface. This may lower cleaning time and water usage costs.

Ozone is a powerful sanitizer that leaves no residual on the surface of equipment or materials. This limits the corrosive potential of ozone and provides a less harsh or even more gentle sanitizer than many of the common chemicals used. Ozone will provide great sanitation results without the harmful effects on metal or wood equipment.

Ozone can be used throughout the day during processing. Since there is no danger in damaging products with harsh chemicals, ozone can be used to sanitize processing equipment throughout the day during normal processing. This may lower down-time and allow for more production hours.

Ozone Tests at Fruit and Vegetable Pilot Plant

Tests conducted in 1999 by California Polytechnic State University at a pilot plant showed the effectiveness of ozone in reducing microbiological loading. The ozone system in use provided a 2.0 ppm dissolved ozone level that was sprayed on the surfaces to be sanitized. No other cleaning methods were used with the ozone to ensure all reductions in bacteria were attributed to the aqueous ozone. The table below shows the results from this test.

Effectiveness of Ozone

| SURFACE | % REDUCTION IN PLATE COUNT |

|---|---|

| Stainless Steel Kettle | 89.7-98.2 |

| Stainless Steel Tabletop | 98.9-99.7 |

| Stainless Shroud | 63.1-99.9 |

| High-Traffic Floor | 67.0-95.6 |

| Low-Traffic Floor | 84.3-99.9 |

| Floor Drain | -- |

| Floor Drain 2nd Attempt | 77.5 |

| Plastic Shipping Containers | 96.9-97.2 |

Use of Ozone for Winery and Environmental Sanitation

By Brian Hampson, PhD, Food Science and Nutrition Dept California Polytechnic State University, San Luis Obispo, CA

Results from Tests at a Fortune 50 Pork Processing Company

Tests were performed at a Fortune 50 Pork Processing Company to determine the effectiveness of aqueous ozone for sanitation of hard surfaces, meat cuts and knife dips. These tests were performed in a working plant in normal working environments. Samples were sprayed with aqueous ozone ranging from 1.1 - 1.4 ppm for about 10-15 seconds. All tests compared microbiological counts on samples before and after ozone, ozone vs 180° F water and ozone vs 180° F water and cold water.

In these tests, ozone performed very well as a sanitizer. Ozone showed a consistent reduction in microbial loading on each material tested. In all tests ozone performed at an acceptable level for sanitation. In many tests, ozone outperformed 180° F water. As these tests were performed in real world environments with fairly conservative ozone levels (1.1 - 1.4 ppm) these results are very realistic and show the potential for ozone use as a surface sanitizer.

Decontamination of a Multilaminated Aseptic Food Packaging Material and Stainless Steel by Ozone

Authors: Mohammed A. Khadre, Ahmed E. Yousef

A multilaminated aseptic food packaging material and stainless steel were treated with ozone to inactivate natural contaminants, bacterial biofilms and dried films of Bacillus Subtilis spores and Pseudomanas fluorescens. Sterility of the multilaminated packaging material was achieved when 1.0 x 2.0 cm-pieces of the naturally-contaminated materials were treated with ozone in water (5.9 μg/mL) for 1 minute. Dried films of spores (108/6.3-cm2 surface) were eliminated by 13 μg/mL of ozone in water for the multilaminated packaging material and 8 μg/mL in case of the stainless steel.

Ozone inactivated Pseudomonas fluorescens in biofilms more effectively on stainless steel than on the multilaminated packaging material eliminated up to ~108 cfu/12.5 cm2. In conclusion, ozone is an effective sanitizer with potential applications in the decontamination of packaging materials and equipment food-contact surfaces.

Studies on the Disinfection and Removal of Biofilms by Ozone Water Using an Artificial Microbial Biofilm System

Gaseous Ozone Applications

Ozone can also be used in the gaseous form to disinfect and sanitize areas. While actual biofilms will not be removed with gaseous ozone, there are applications where this may be a suitable solution. Many applications do not allow for water to penetrate locations where bacteria may reside and cause future cross-contamination. Gaseous ozone has been used for many years for odor control, mold remediation and other disaster restoration services. The same action used to remove odor and mold spores can be used to kill bacteria and mold in industrial settings.

Results from Gaseous Ozone Applications

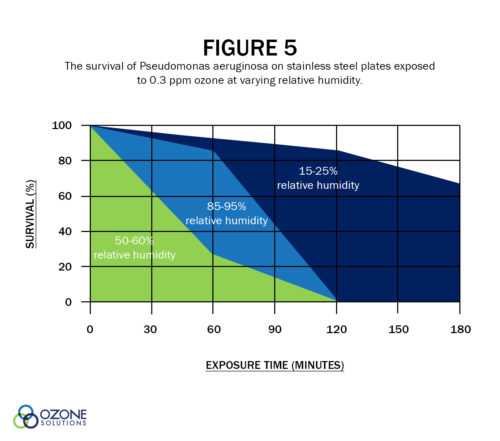

The use of gaseous ozone has been tested in various forms for many applications. A wide variety of applications from hospital rooms to sports gear, such as hockey equipment, have used gaseous ozone for disinfection. When using aqueous ozone for surface sanitation, the two main variables that affect the success of ozone are contact time and ozone levels. When using gaseous ozone a new variable, humidity, will dramatically affect the results. The level of humidity in the environment will affect the ability of ozone to penetrate and destroy microorganisms. The following research will show a new variable affecting the results of microbiological reduction with ozone.

Results from the Study on Ozone Use for Surface Disinfection

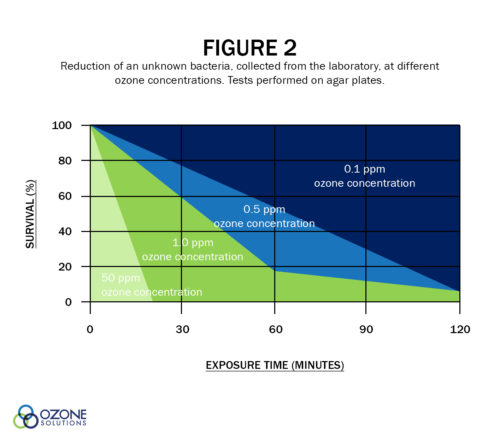

This study investigated the potential of gaseous ozone to inhibit growth of microorganisms on surfaces. This study evaluated the effectiveness of ozone at varying ozone concentrations, for various contact times, at varying relative humidity.

This study investigated the potential of gaseous ozone to inhibit growth of microorganisms on surfaces. This study evaluated the effectiveness of ozone at varying ozone concentrations, for various contact times, at varying relative humidity.

The effect of ozone on Apergillus Niger, Pseudomonas Aeruginosa and a mix of microorganisms was tested. Highly contaminated surfaces were exposed to ozone gas at various levels ranging from 0.1 to 5,000 ppm in these tests. Exposure times from 20 minutes to 120 minutes were used at low ozone levels, while exposure times of 0.33 minutes to 20 minutes were used at 5,000 ppm.

Humidity showed a great affect on the reduction of bacteria in the presence of ozone gas. Altering the humidity level from 15-25% to 85-95% showed a greater change in bacterial reduction than altering the ozone level in some tests.

Humidity showed a great affect on the reduction of bacteria in the presence of ozone gas. Altering the humidity level from 15-25% to 85-95% showed a greater change in bacterial reduction than altering the ozone level in some tests.

When high concentrations of microorganisms on agar plates placed in the test chamber are exposed to high levels of ozone, 5.0 ppm, the destruction was enormous. The results are shown below.

Table 1: The survival of high concentrations of microorganisms exposed to high ozone concentration during shorter exposure times.

| Microorganism | Exposure Time (minutes) | Control (CFU) | Survival (%) |

|---|---|---|---|

| Aspergillus niger | 0.33 | 3*10* | Too numerous to count |

| 5.00 | 3*10* | 0.27 | |

| 20.00 | 3*10* | 0.19 | |

| Pseudomonas Aeruginosa | 0.33 | 1*10* | 0.004 |

| 5.00 | 1*10* | 0.0004 | |

| 20.00 | 1*10* | 0 | |

| Mix of Microorganisms | 0.33 | 5*10 4 | Too numerous to count |

| 5.00 | 5*10 5 | 0.0018 | |

| 20.00 | 5*10 6 | 0.0016 |

White Paper Abstracts

Decontamination of a Multilaminated Aseptic Food Packaging Material and Stainless Steel by Ozone

Original White Paper Go to Page

Inactivation of Vegetative and Sporulated Bacteria by Dry Gaseous Ozone

Ozone: Science & Engineering, Volume 32, Issue 3, 2010, pages 180-198 Authors: Ahlem Mahfoudh, Michel Moisan, Jacynthe Seguin, Jean Barbeau, Yassine Kabouzi & Danielle Keroack Go To Page

The Practical Application of Ozone Gas as an Anti-Fungal (Anti-Mold) Agent

Ozone: Science & Engineering, Volume 31, Issue 4, 2009, pages 326-332 James B. Hudson & Manju Sharma http://www.tandfonline.com/doi/abs/10.1080/01919510903043996

An Evaluation of the Antimicrobial Effects of Gas-Phase Ozone

Ozone: Science & Engineering, Volume 31, Issue 4, 2009, pages 316-325 James B. Hudson & Manju Sharma http://www.tandfonline.com/doi/abs/10.1080/01919510903043772