Ozone Venturi Injector

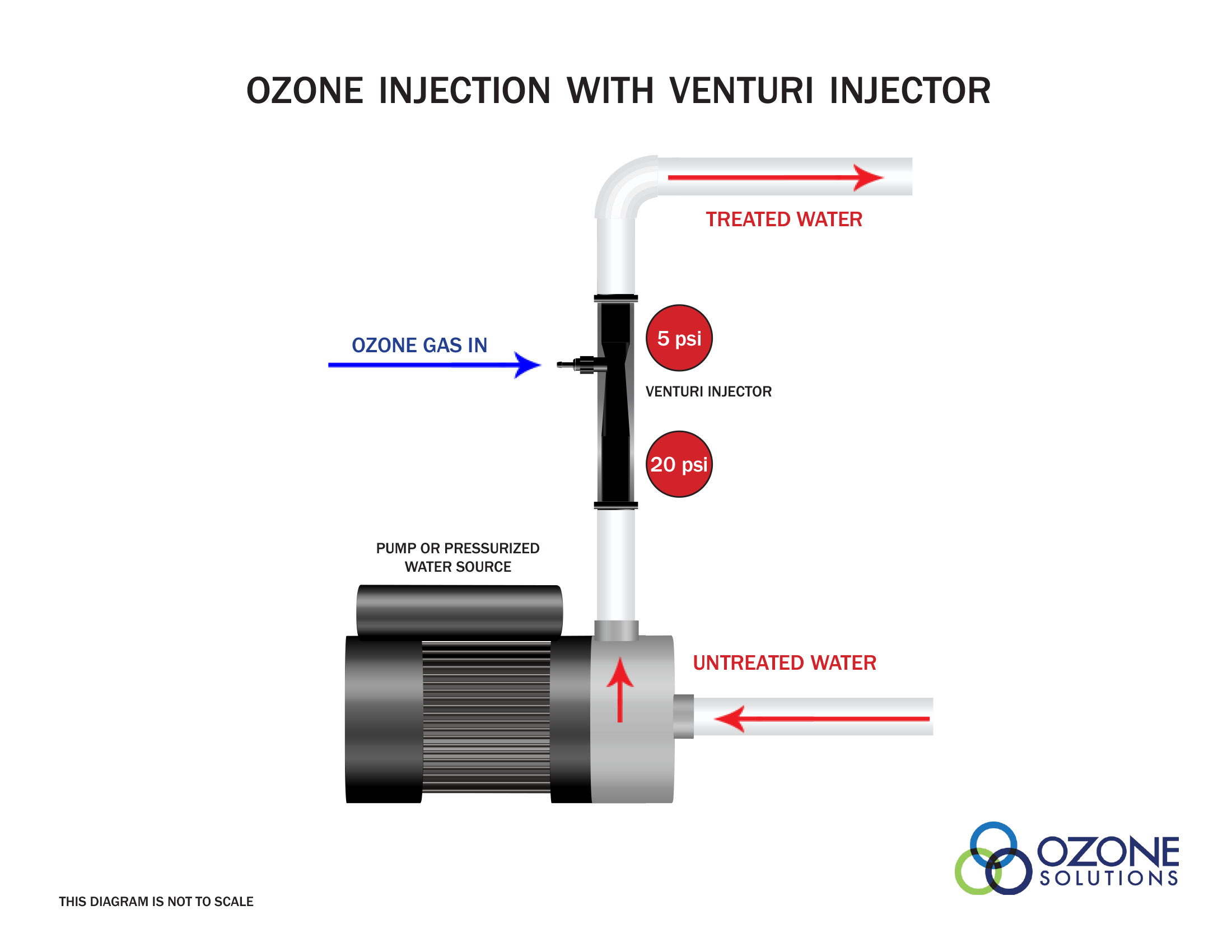

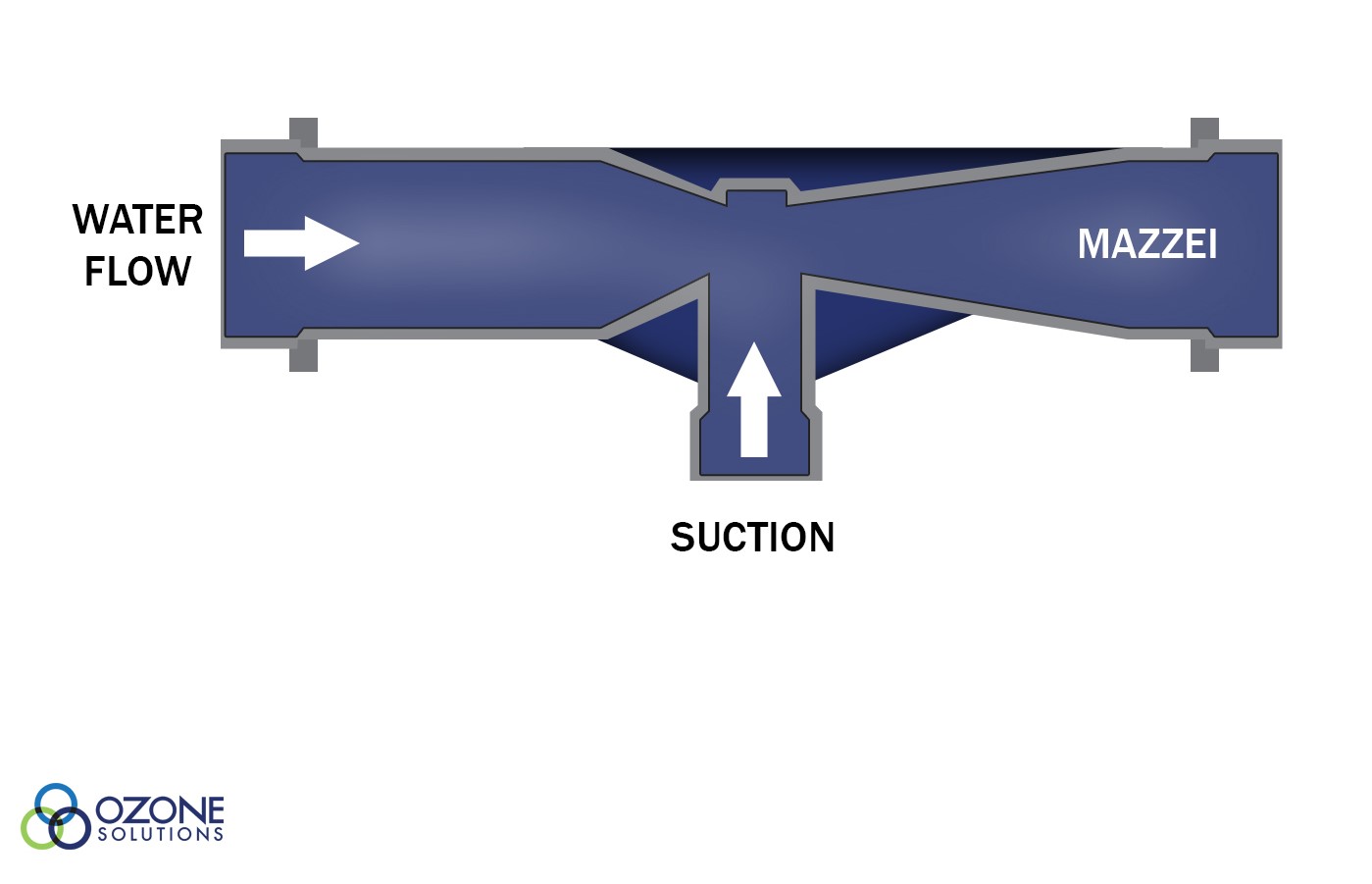

A popular method for adding ozone gas into water through the use of venturi injectors. Venturi injectors work by forcing water through a conical body.

This action creates a pressure differential between the fluid inlet and outlet ports, which in turn creates a vacuum inside the injector body. This vacuum now allows the ozone gas to be added into the flowing water stream via the suction port on the injector.

Advantages:

- Very high ozone mass transfer rate (up to 98% if pressurized, 50-70% w/out pressure)

- Minimal maintenance required

- More controlled & consistant over time

- Works well in both pressurized and unpressurized fluid streams

Disadvantages:

- Requires energy from a booster pump or pressurized water supply to achieve the 98% transfer otherwise it can give you 50-70%

- A very high liquid to gas ratio is required to achieve 98% mass transfer efficiency. In fact, the ratio required would not be economical. Typical mass transfer efficiencies for venturi injectors are from 50-70% (without the use of pressure).

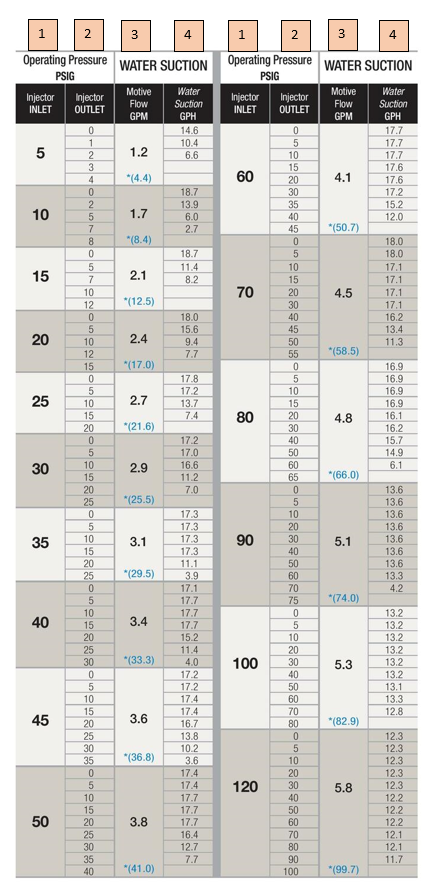

Below is a chart for a very popular ozone injector. The injector is capable of injecting both liquids and gases. For ozone, we can completely ignore the third and fourth columns because they apply to liquid suction only.

*Note: The terms "venturi" and "injector" are used synonymously in the ozone industry.

Example

A pump delivering 18 gpm @ 15 psi can inject a maximum of 20 SCFH (10 lpm) of air if 7 psi of back pressure exists.

If more suction is needed, two options exist: Increase the size of the pump or decrease injector outlet pressure by increasing the diameter of the pipe, reducing the number of elbows or lowering the height of the delivered water.

psig = pounds per square inch gauge

gpm = gallons per minute

SCFH = standard cubic feet per hour

The first column is the injector inlet pressure, which is the pressure provided from a pump. The 2nd column is the injector outlet pressure, which is the pressure exerted on the injector outlet from delivering the water where it needs to go. The 3rd column called MOTIVE FLOW states the flow rate of water going through the injector. The last column called AIR SUCTION lists the amount of air or ozone that can be sucked into the water stream.

As can be seen from the chart, as the injector outlet pressure increases (2), injector suction (4) decreases. This is true even though the motive flow (3) stays relatively constant.