Product Overview

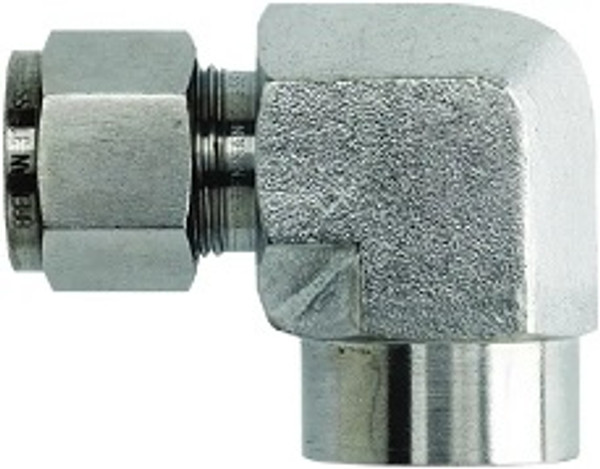

The demand for the Compression Tube Fittings are very high because of its amazing properties, thus we supply customer such fitting as per the customer's requirements. Compression Fittings are a very common method in which the connection of metals and hard plastic tubing is done.

Stainless Steel is also a very versatile method; therefore, it is largely used in extreme conditions where the temperature is very high as well low. Additionally, it also exhibits high pressure bearing abilities and its compatibility with an aggressive type of fluids is just great. This is the main reason for which compression fittings are popularly seen in the systems ranging from gas lines in the refineries to the plumbing systems under the sink. There are many types of Compression Tube Fittings and it is also available in different shapes, sizes, structures, standards, specifications, grades, thickness, dimensions, designations, alloys, etc.

These fittings are the absolute top-of-the-line option for stopping ozone tubing leaks. Guaranteed to work. Ideal for environments where vibration is present.

|

304 Stainless Steel

|

316 Stainless Steel

|

|

|

Corrosion Resistance

|

|

|

|

Typical Applications |

|

|

Warranty Information

California Regulatory Warning

Health hazard warning: emits ozone.

This product is not CARB Certified (Ozone Emissions for Air Cleaners).

Product Disclaimer: Does not meet California air cleaner regulation requirements; cannot be shipped to California.