Ozone Sensor Technology Comparison

Not all ozone detection devices are created equal! This page compares the various technologies that are commonly used to detect ozone: Electrochemical sensors, semiconductor-based sensors (HMOS / GSS), UV absorption and color-change badges.

Read on to discover the details of each technology and find our side-by-side comparisons below.

Read on to discover the details of each technology and find our side-by-side comparisons below.

Electrochemical Ozone Sensor

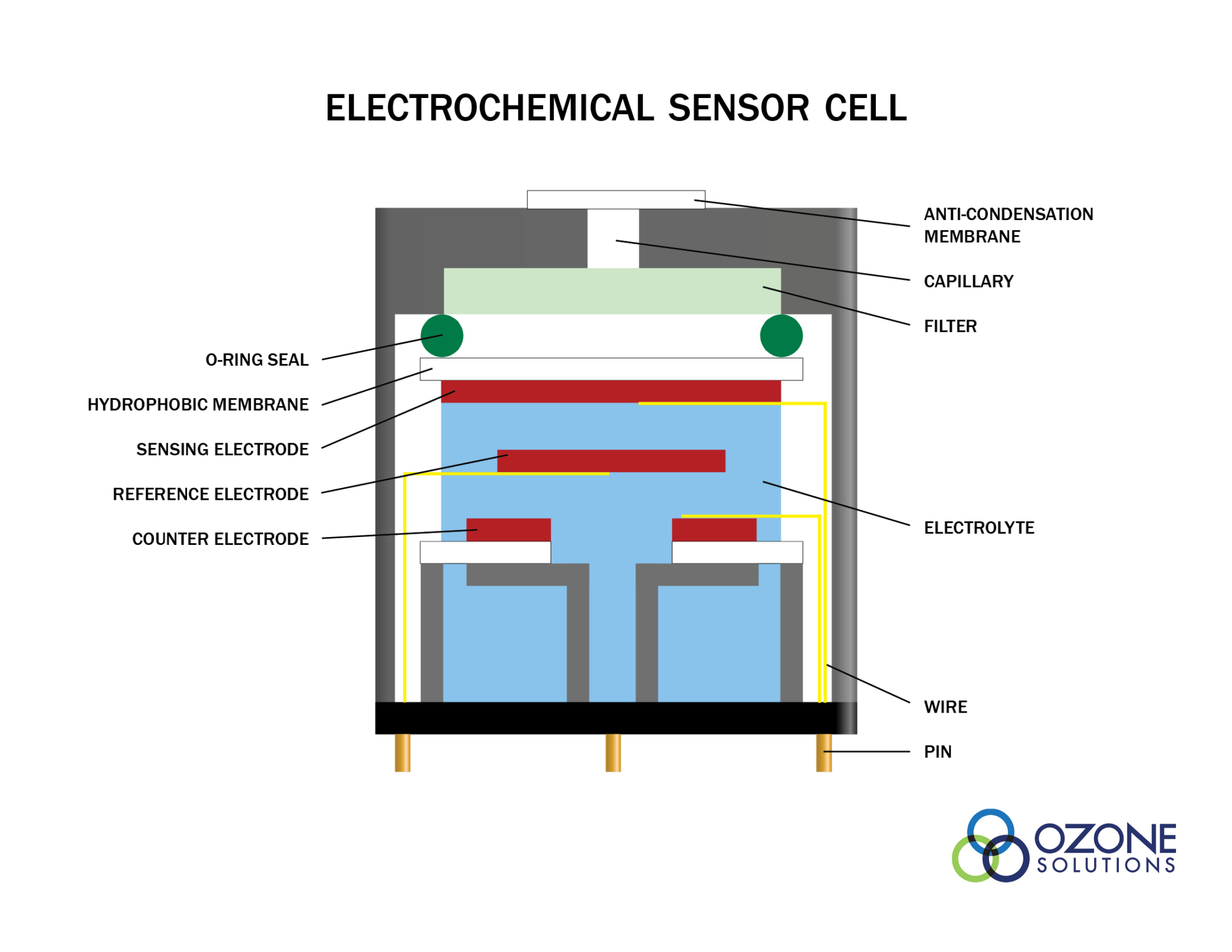

An electrochemical ozone sensor uses a porous membrane that allows ozone gas to diffuse into a cell containing electrolyte and electrodes. When ozone comes into contact with the electrolyte, a change in electrochemical potential occurs between the electrodes causing electrons to flow.

In zero air, little or no electron flow occurs. As the presence of ozone increases, the electrical signal increases proportionally. The monitor interprets this signal and displays the ozone concentration in ppm (parts per million).

Advantages

- Linear response

- Good repeatability and accuracy

- Very quick response time (1-2 seconds)

- Long battery life

- Can measure ozone accurately up to 20 ppm

- Moderate resistance to interference

Disadvantages

- Humidity can affect sensor readings

- Sensitive to EMF/RFI

- Limited sensor life (often max of 12-18 months), even if in storage

- Decreased accuracy at low ozone levels (below 0.1 ppm)

Applications

- Personnel (portable) safety monitoring (especially for shift-long use)

- Ozone leak detection

- Stationary ambient ozone monitoring

- Ozone control scenarios (alarms, exhaust fans, ozone generators, etc.)

Semiconductor-Based Ozone Sensor

Heated Metal Oxide Sensor (HMOS) / Gas Sensitive Semiconductor (GSS)

A heated metal oxide semiconductor (HMOS) sensor works by heating a small substrate to high temperature (around 300° F / 149° C). At this temperature, the substrate is very sensitive to ozone and exhibits a change in resistance that is proportional to to the amount of ozone which contacts its surface. The circuitry of the monitor interprets this change in resistance and displays the corresponding ozone level on the display as either ppm or ppb.Advantages

- Very responsive to low levels of ozone ozone (below 0.1 ppm)

- Least expensive monitoring technology

- Excellent repeatability and accuracy

- Long sensor life if stored properly

Disadvantages

- Slow start-up (can require 8-24 hours warm-up time)

- Slower response time to ozone (compared to electrochemical)

- Very sensitive to interference

- Shorter battery life due to heated sensor element

- Not linear at ozone levels above 1 ppm

- Maximum temperature threshold of 122°F or less (depending on model)

Applications

- Ambient ozone safety monitoring (especially below 0.1 ppm)

- Portable ozone monitoring (especially below 0.1 ppm)

- Ozone control scenarios (especially below 0.1 ppm)

- Ozone leak detection

UV Absorption

UV Absorption

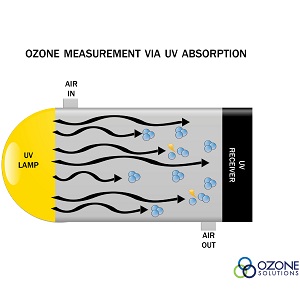

An ozone molecule has a UV absorption maximum at 254 nm. In a controlled environment this means that the amount of 254 nm UV light absorbed in an airspace is proportional to the amount of ozone present.

UV ozone analyzers take advantage of this property of ozone for stable, accurate readings. A UV lamp emitting light at a wavelength of 254 nm produces a controlled amount of light within a sealed chamber. This UV light is measured via a photodiode that is also filtered to detect at the 254 nm wavelength.

The difference in UV light produced at one end of the chamber vs the UV light measured at the other end of the chamber,indicates the concentration of ozone in the air sample which is then displayed on-screen or output to a control system.

Advantages

- Very accurate (within 1%)

- Very linear at any ozone levels

- Low ppb detection limits with accuracy

- Minimal cross sensitivity to other gasses or interferences

- Can read high concentrations (20% or higher)

- Durable design with excellent longevity

Disadvantages

- Higher cost than electrochemical or HMOS / GSS

- Physically larger technology

Applications

- Low Concentration

- Cold storage facilities

- Microarray applications

- Semiconductor fabrication facilities

- Ozone compatibility testing

- Medium concentration

- Off-gas monitoring

- High concentration

- Industrial ozone generator control

- Ozone research

- Ozone compatibility testing

Ozone Badges / Ozone Test Strips

Ozone badges are cards that use a color change indicator. The indicator used is a small paper strip or circle that is oxidized in the presence of ozone. The amount of oxidation (color change) that occurs during a set amount of time is proportional to the amount ozone present in the air.Advantages

- Easy-to-use

- Low cost

- Specific to OSHA 8 hour ozone limit (PEL)

Disadvantages

- One-time use (or limited use) cards

- Very cross-sensitive to some other gases

- Generally limited to ~0.1 ppm detection limits

Applications

- Initial determination for presence of ozone

- Temporary personnel monitoring needs

- Widespread employee-level ozone monitoring

- Residential use

How Do They Compare?

Now that you have an overview of the various technologies, you may want to know how they rate for various metrics. See the lists below!Ranked by Resistance to Interference

(Descending order, from best to least)

- UV Absorption (best)

- Electrochemical

- HMOS / GSS

- Ozone Badges

Ranked by Price

(Descending order, from highest to lowest)

- UV absorption

- Electrochemical

- HMOS / GSS

- Ozone Badges

Ranked by Operating Temp. Range

(Descending order, from widest operating band to narrowest)

- Electrochemical

- UV Absorption

- HMOS / GSS

- Ozone Badges