Poultry

Poultry processors are constantly looking for more effective ways to keep birds, facilities, and equipment clean and free from dangerous contamination. Microbial disinfection is essential for consumer safety with ever-growing global consumer demand.

With ozone’s ability to be used in gaseous and aqueous applications and at most steps in poultry lifecycle and processing, it provides distinct advantages over other disinfectants for poultry producers. Ozone is ideal for hatcheries, feed mills, grow-out, first and second processing, warehouse, and even trailer washout.

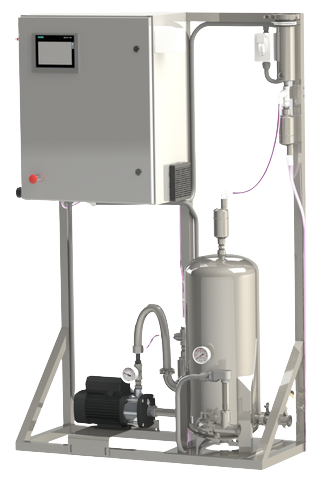

Our extensive ozone generator line addresses contamination at each stage of processing. From products to eliminate odor and airborne contaminants (Airzone) to aqueous ozone generators for various environments (Waterzone Series, Waterzone SE Series, Waterzone IS Series), and combination aqueous/gaseous units (Dualzone), we offer products in numerous configurations.

Ozone Benefits for Poultry Processing & Storage:

- Approved by the FDA, USDA and supported by the National Organic Program

- Removes airborne microbiological and improves odors

- No harmful chemical residues that require a final rinse

- 3000x more germicidal than chlorine

- Lower cost of wastewater disposal

- Instant pathogen destruction

Water and energy efficiency

Water and energy efficiency- Environmentally friendly

- Ethylene removal

- Longer shelf life

We understand no two operations are the same. Our design and consultancy services enable you to tailor a system to your specifications. From evaluating your current system to assuring accurate sizing to installation oversight, our engineering and design team can help you at any project stage.

| Common Systems Used In The Poultry Industry | ||

|---|---|---|

| MobileZone | WaterZone Series | WaterZone IS Series |

|  |  |

| Up to 40g/hr ozone production | Produces ozone from integrated Oxygen Concentrator | Produces ozone from integrated Oxygen Concentrator |

| Capable of producing ambient and dissolved ozone | Will provide 100 GPM Water Flow with 2.0 PPM Dissolved Ozone Level | Automatic operation - one touch start up and shut down |

| Compact, mobile design | Customizable system can be configured for your specific application | Customizable system can be configured for your specific application |

| Ozone Destruct included for added safety | All plumbing and fittings are stainless steel | High efficiency with excellent mass transfer of ozone |

| MobileZone | WaterZone Series | WaterZone IS Series |